CIP or Cleaning in Place

- | آتاماد |

- Viewer: 542

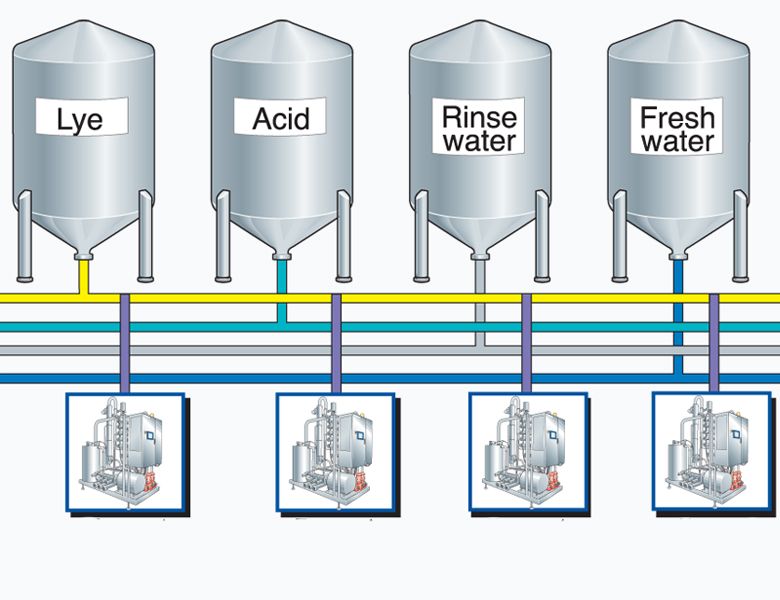

CIP or Cleaning in Place is a practical method for equipment in the food industry. CIP cleaning includes automatic cleaning and disinfection without removing the equipment. Rinsing and rinsing CIP can also be defined as circular rinsing with liquid flow. The CIP system is compatible with different parts of the factory and is installed in order to achieve good results in cleaning place and lines.

Cleaning occurs in process pipes, tanks, heat exchangers, and other equipment to prevent contamination of the product and to maintain process efficiency. This operation is not only the first step in the production process, but also a continuous process during the day and the last stage after the end of production.

To perform an effective CIP, all equipment and surfaces must be flushed in the circuit, so that they can be washed easily and properly. Also, equipment and pipelines should not be in blind areas, as this will prevent detergents from accessing them.

Detergents used in the CIP system are alkaline or acidic. Alkaline detergents include: sodium hydroxide, potassium hydroxide, sodium carbonate, etc., and in the case of acid detergents, we can mention hydrochloric acid, nitric acid, phosphoric acid and citric acid. Alkaline cleaners are those cleaners whose pH is higher than 7 and are commonly used in the dairy industry. Because it converts fat into soap and is washed away with water.

CIP systems are generally classified into three categories:

1) In a single system, water and solutions are sent to all lines and discharged immediately after a CIP cycle.

2) Multifunctional systems recover high quality chemicals, and antifouling solutions and water are usually reused with increasing strength.

3) Complete recovery systems (commonly known as CIP reuse or CIP recovery systems) are complex and automated. These systems are very economical in terms of water consumption.

Benefits of applying CIP system:

• Reduce manual work due to cost and reliability

• Save on reducing water and chemical consumption

• Reduce waste and effluent

• Reduce the risk of re-contamination by reassembling equipment after cleaning and disinfection

• Reduce potential for occupational health and safety (OHS) injury to operators

Hygiene principles for CIP systems rely on four main factors: time, temperature, concentration, and mechanical force, all of which are interrelated.

Time:

The circulation of detergents can last up to an hour, depending on the concentration and amount of contamination. (For example, long periods in the production of milk, pasteurizer and evaporator can lead to sediment or biofilm, which will be more difficult to remove).

Temperature:

The effectiveness of washing depends on the severity of this factor; before washing with detergent, the equipment is washed with cold water. Excessive temperatures of cleaning solution may ‘bake-on’ remaining milk protein soil, making it difficult to remove.

Chemical concentration:

Concentrations of chemicals and disinfectants should be maintained within the specified limits. Because these materials are not well cleaned and disinfected in low concentrations and too high concentrations reduce the efficiency and corrosion of equipment.

Mechanical force:

To ensure accurate CIP performance, all surfaces and equipment must come into contact with cleaners and disinfectants, and this is possible with the help of sufficient mechanical force through the flow. The cleaning fluid moves at a fluid velocity of approximately 1.5 to 3 m/s.

The CIP cycle:

1) Initial washing with water: (Depending on the composition of the product, this water can be hot or cold) Pre-washing is a very important step in this process, because a very good and controllable pre-wash has a good effect on the continuation of the washing cycle. The purpose of this step is to remove contaminants and loosen the bond of product residues on the equipment surfaces.

At this stage, the inner surface of the tanks and lines are moistened, most of the residual material is lost, the sugars are dissolved and some of the fats are melted.

2) Cleaning chemical wash: At this stage, the fats are softened for easier removal and NaOH sodium hydroxide is used in a concentration of 2-5% at temperature of 70-90°C for 20 minutes. (Concentrations above 4% may also be used for highly contaminated surfaces).

3) Rinsing: All equipment and surfaces are thoroughly rinsed in order to remove chemicals.

4) Washing with acid: at this stage, washing with acid (HNO) with a concentration of 0.5% at a temperature of 60-70°C is done for 10-15 minutes. The purpose of this step is to reduce the microbial load and create a clean and safe surface.

5) Final rinse: this step may be necessary to help kill the microorganisms before starting the next production. This step is necessary to clean the disinfectant and create a clean, chemical-free path. Because it is economically viable. Chlorine is potentially harmful to stainless steel and causes stains, corrosion and cavities. In recent years, most manufacturers have turned to per-acetic acid (PAA), a combination of hydrogen peroxide and acetic acid.

GET IN TOUCH

Copyright © 2023 Atamad.com All right reserved

Website design and SEO services by Seohama team – Web hosting by Sarverhama

Copyright © 2023 Atamad.com All right reserved

Website design and SEO services by Seohama team – Web hosting by Sarverhama