Lactose Intolerance and free-lactose dairy

- | آتاماد |

- Viewer: 361

Lactose, a sugar in milk, is the principal carbohydrate in milk from most mammals, including humans, and makes up about 40% of the total energy requirement of infants during the first year of life. Human breastmilk contains about 7.5% lactose, whereas bovine milk contains about 4.5%

Lactase is produced by villi in the small intestines, where it breaks down lactose into monosaccharides glucose and galactose. Lactase deficiency or insufficient amounts of lactase production results in Lactase malabsorption.

As a result, undigested lactose enters the colon where colonic microbiota converts it to fermentable glucose. The fermented glucose, consequently produces short-chain fatty acids and gases, developing gastrointestinal symptoms like abdominal pain, diarrhea, gas, bloating, and/or nausea. The onset of symptoms is dependent on the dosage of lactose, lactase expression levels, intestinal flora, and sensitivity of the gastrointestinal tract.

Lactose deficiencies

There are four different types of lactase deficiency that may lead to LI.

• Primary lactase deficiency (hypolactasia)

This type of lactase deficiency is related to the decreased levels of lactase production by approximately 90-95% over time. An adaptation of gut microbiota by increasing the lactos dosage may increase the activity of bacterial β-galactosidase, thus reducing LI symptoms.

• Secondary lactase deficiency (Secondary hypolactasia)

Gastrointestinal infections and diseases may temporarily interfere with lactase expression, diseases like gastroenteritis, coeliac disease Crohn’s disease, and chemotherapy.

• Developmental lactase deficiency

The third type of lactase deficiency occurs in prematurely borne infants. As infant ages, the ability to produce lactase improves.

• Congenital lactose deficiency.

An extremely rare autosomal recessive disorder, alactasia is a state in which small intestines produce very little to zero lactase enzyme from the very moment of birth. The inability of infants to digest lactose in breast milk or non-lactose-free infant formula result in severe diarrhea, dehydration, and weight loss.

Consumption of lactose-free products may help reduce symptoms of lactose intolerance. People with this disorder can take advantage of calcium and vitamins available in lactose-free dairy products without facing any problems. In recent years, lactose-free dairy has had a growing demand in the market. By offering diverse and innovative products, manufacturers can improve the product’s quality by enhancing characteristics like taste and texture, and cost reduction.

Lactose-free dairy market

Dairy products contain different amounts of lactose. Fermented products such as yogurt, fresh cheeses, sour cream, ice cream, kefir, and products made from whey, contain a lot of lactose. On the other hand, in aged cheeses, Lactose content is low, such as Parmesan, Swiss, and Cheddar cheeses. Among other dairy products, lactose content in butter is <0.1%.

In recent years with an increase in consumption of lactose-free products, there has been a fast development in the production of such products. The total growth of such dairy products belongs to lactose-free milk, yogurts, and cheeses respectively. There is no global consensus on the regulatory requirements for lactose-free claims, the general trend, however, is to reduce the lactose content as low as possible.

Production of Lactose-Free Dairy

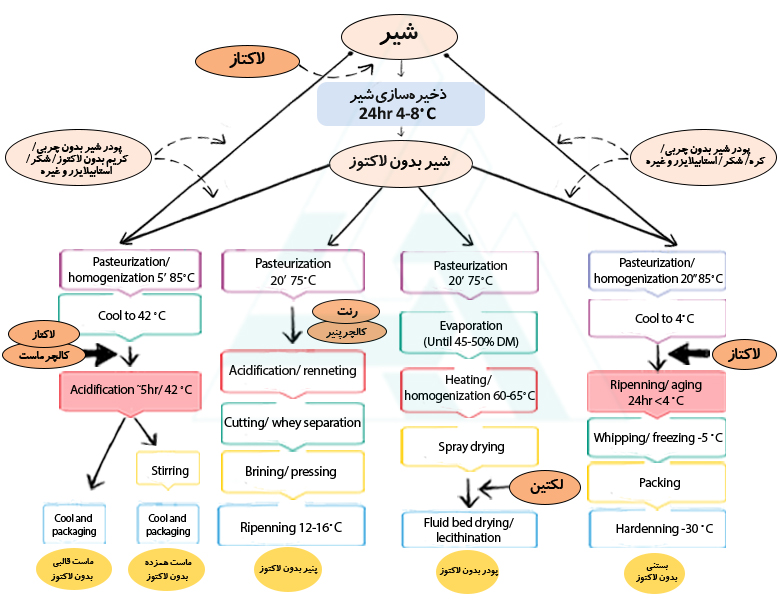

• Milk

Extra sweetness due to lactose hydrolysis is not attractive to some consumers. So, alternative lactose-removal technologies have been established to remove additional sweetness i LF milk, including membrane filtration or chromatography. Typically, around 50% of the lactose is removed by filtration, and the remaining lactose is subsequently hydrolyzed using lactases, which results in LF milk with a sweetness similar to that of regular milk.

• Yogurt

lactose-intolerant people will have a problem with dairy products containing substantial amounts of lactose, 30–40 g/kg. However, this seems to be much less the case than expected from the amount of lactose that is consumed. There have been two different theories to explain this phenomenon, 1) The lactic acid bacteria present in yogurt will survive the stomach, and the bacterial lactase enzyme helps the digestion of the lactose. The monosaccharides are then absorbed in the small intestine. 2) Due to the decreased transit time of a viscous yogurt meal compared to liquid milk the lactose in yogurt is better digested. So, there is more time for any residual lactase to digest lactose.

The complete digestion of lactose in yogurt, the most reliable remedy, can be done by incubating the milk with lactase before pasteurization (similar to the batch process for milk), or adding the lactase together with the culture after the pasteurization of the milk. Most yogurt producers opt for the latter, co-hydrolysis, approach since predigestion seems to inhibit the activity of some yogurt cultures, probably due to the switch from lactose to glucose as a main carbon source or to the increased osmotic pressure in lactose-hydrolyzed milk.

Most neutral lactases are inactivated at a pH< 5.5, which is reached after 2.5-3 hours of incubation in a regular yogurt making process. So, a limited time for lactose digestion is left. Thus, to obtain a lactose-free status, a relatively higher dosage of the enzyme or acid-stable lactases should be applied. Acid-stable lactases are not inactivated by the low pH, reducing the total enzyme dosage.

Reduced added sugar to 1.5-2 g/100 g without changing the flavor profile, and reduced post-acidification during shelf-life, are advantages of lactose digestion in yogurt.

• Cheese

In the production of lactose-free cheese, lactase is combined with milk before adding rennet and starter culture. In ripened cheeses, all the lactose is broken down by the existing bacteria and there is no need to use lactase, but it has been used in the past to help acidify and increase the taste.

• Flavored milk

The process is similar to the LF milk process. Flavored LF milk also has much fewer problems with Maillard-related off-flavors and browning than regular lactose-free UHT milk, since the product often has a strong flavor and color by itself. For some flavored milks, like highly sugared chocolate milk, lactose hydrolysis may be insufficient to fully replace all sugar addition.

• Dairy powders

Dairy powders can be produced from milk or whey that is made LF via the batch process. The presence of a high concentration of monosaccharides in the treated milk is a major problem that leads to a drop in the glass-transition temperature. Hence, this product will lead to the fouling of the spray dryer when the drying conditions are not adapted. The much milder spray drying conditions lead to dramatic decreases in the productivity of the drying process and increased costs. Moreover, the LF milk (or whey) powder is highly hygroscopic, leading to caking during storage. Due to these challenging technical problems, LF dairy powder is still a small market.

• Ice cream

LF Ice cream can be produced by either using LF milk and powders or by adding the lactase enzyme after pasteurization and incubation during the aging period before freezing. The decrease in the freezing point of the product is due to the increase in monosaccharide content after lactose hydrolysis leads, resulting in softer ice cream. Because of the “soft scoop,” this may be an advantage for some frozen desserts, but it will also lead to faster melting. Since the sweetness increases, the sugar addition can be decreased, and, thereby, the melting temperature increases again. Moreover, lactase treatment is also used to prevent lactose crystallization in ice cream. Especially when whey powder or WPC is used in the ice cream mix, the amount of lactose may be high enough to form crystals during freezing, leading to sandiness sensory defect. Lactase treatment can prevent the formation of sandiness in ice cream by splitting lactose into glucose and galactose, which are more soluble at low temperatures. It was found that lactose hydrolysis decreases the freezing point and sandiness, increases the apparent viscosity of the ice cream mix and sweetness, thus allowing a 25% reduction in sugar addition, and generally improves the overall acceptability of ice cream.

Benefits like easing discomfort from lactose intolerance, improving quality characteristics like taste and texture, and reducing costs could reach by taking advantage of lactase properties in the production of dairy products like dairy powders, ice cream, cream, and desserts.

References:

- Peter J. T. Dekker, Damiet Koenders, and Maaike J. Bruins. “Lactose-Free Dairy Products: Market Developments, Production, Nutrition and Health Benefits.” Nutrients, 2019 Mar; 11(3): 551; doi:10.3390/nu11030551.

- Lactose-free milk: Lactose intolerance, nutrition and process technology, by Signe Christerson, 2021.

GET IN TOUCH

Copyright © 2023 Atamad.com All right reserved

Website design and SEO services by Seohama team – Web hosting by Sarverhama

Copyright © 2023 Atamad.com All right reserved

Website design and SEO services by Seohama team – Web hosting by Sarverhama