- آتاماد

- Biodegradable packaging 2

Biodegradable packaging 2

- | user2 |

- Viewer: 910

Biodegradable packaging 2,Types of polymers used in making biodegradable packaging:

Poly lactic acid (PLA):

One of the most promising biopolymer is the poly (lactic acid) (PLA) obtained from the controlled depolymerization of the lactic acid

monomer obtained from the fermentation of sugar feedstock, corn, etc. which are renewable resources readily biodegradable. It is produced by conversion of corn, or other carbohydrate sources, into dextrose, followed by a fermentation into lactic acid. It is a versatile polymer, recyclable and compostable, with high transparency, high molecular weight, good processability and water solubility resistance. In addition, the production of PLA has been reported to result in 15% to 60% lower carbon emissions and 25% to 55% lower energy consumption than petroleum-based polymers. In general commercial PLA is a copolymer between poly (L-lactic acid) and poly (D-lactic acid).

Cellulose:

Cellulose is the most widely spread natural polymer and is derived by a delignification from wood pulp or cotton linters. It is a biodegradable polysaccharide which can be dissolved in a mixture of sodium hydroxide and carbon disulphide to obtain cellulose xanthate and then recast into an acid solution (sulfuric acid) to make a cellophane film. Alternatively, cellulose derivatives can be produced by derivatization of cellulose from the solvated state, via esterification or etherification of hydroxyl groups. Especially these cellulose derivatives were the subject of recent research. Cellulose esters like cellulose (di)acetate and cellulose (tri)acetate need addition of additives to produce thermoplastic materials. Most of them can be processed by injection molding or extrusion. Cellulose ethers like hydroxypropyl cellulose and methyl cellulose are watersoluble, except for ethyl cellulose and benzyl cellulose. Most of these derivatives show excellent film-forming

properties, but are too expensive for bulk use.

Starch:

Starch is awidely available and easy biodegradable natural resource. To produce a plastic-like starch-based film, highwater content or plasticizers (glycerol, sorbitol) are necessary. These plasticized materials (application of thermal and mechanical energy) are called thermoplastic starch (TPS) and constitute an alternative for polystyrene (PS). Starch-based thermoplastic materials (e.g. blends of TPS with synthetic/ biodegradable polymer components, like polycaprolactone, polyethylene-vinyl alcohol or polyvinyl alcohol) have been successfully applied on industrial level for foaming, film blowing, injection molding, blow molding and extrusion applications.

Commercial polymer coming from the synthesis of oilbased monomer can be mixed with different percentage (10, 50 and 90%) of starch used as additive. Depending on starch percentage and other materials like additives (colouring additives, flame retardant additives) the properties of these materials can be varied a lot, becoming stable to unstable for example in hot/cold water.

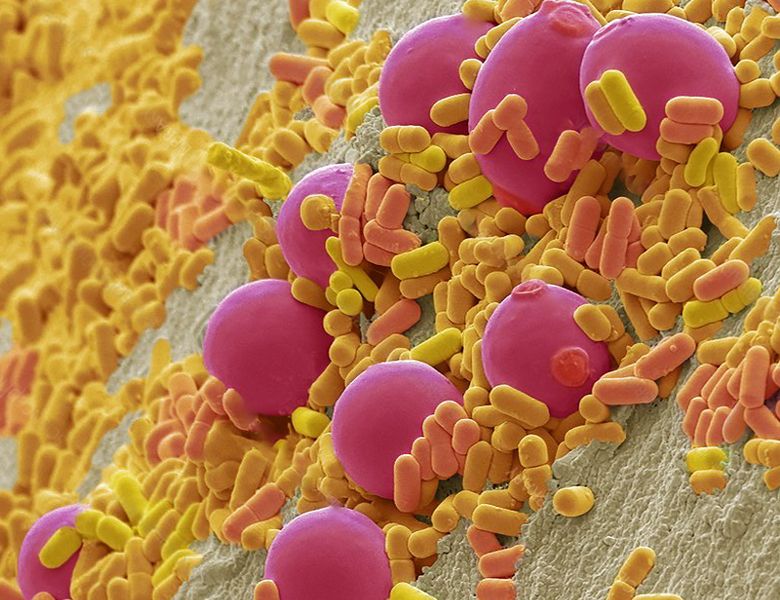

Polyhydroxyalkanoates (PHA):

These polymers are produced in nature by bacterial fermentation of sugar and lipids. They can be thermoplastic or elastomeric materials, with a melting point between 40_C and 180 _C, depending on the monomer used in the synthesis.

These polymers, alone or in combination with synthetic plastic or starch give excellent packaging films. The most common type is the polyhydroxybutyrate (PHB), coming from the polymerization of 3-hydroxybutyrate monomer, with properties similar to PP but more stiffer and brittle. The copolymer polyhydroxybutyrate-valerate (PHBV), used as packaging material, is less stiff and tougher. The price is very high but it degrades in 5e6 weeks in a microbiology active environments, giving carbon dioxide and water in aerobic condition. In anaerobic environment the in aerobic condition. In anaerobic environment the degradation is faster, with production of methane.

By,

ATAMAD technical support sector

Reference:

Siracusa V, Rocculi P, Romani S, Rosa M. 2008. Biodegradable polymers for food packaging: a review. Food Science & Technology, 19: 634-643. https://doi.org/10.1016/j.tifs.2008.07.003

Intan S. M. A, Tawakkal, Marlene J, Cran, Joseph Miltz, and Stephen, Bigger W. 2014. A review of poly (Lactic Acid)-based materials for antimicrobial packaging. Journal of Food Science, 79: 1477-1490. https://doi.org/10.1111/1750-3841.12534

Peelman N, Ragaert P, De Meulenaer B, Adons D, Peeters R, Cardon L, Van Impe F, Devlieghere F. 2013. Application of bioplastic for food packaging. Trends in Food Science & Technology, 32:128-141. https://doi.org/10.1016/j.tifs.2013.06.003

GET IN TOUCH

Copyright © 2023 Atamad.com All right reserved

Website design and SEO services by Seohama team – Web hosting by Sarverhama

Copyright © 2023 Atamad.com All right reserved

Website design and SEO services by Seohama team – Web hosting by Sarverhama