- آتاماد

- ESL MILK (second part)

ESL MILK (second part)

- | user2 |

- Viewer: 833

ESL MILK (second part), ESL (extended shelf life) milk is labelled as ‘longer-lasting’, but just like regular fresh milk, it must be stored in the chiller or in the fridge.

As its name suggests, the ‘longer-lasting’ milk does not spoil as quickly as fresh milk. Whereas traditional fresh milk can be stored unopened in the fridge for six to twelve days, an unopened bottle or carton of ESL milk stored in the fridge (maximum 8 °C) will keep for 21 to 30 days. UHT milk, by contrast, can be stored at room temperature for up to 12 weeks. In terms of shelf life, ESL milk is therefore positioned between traditional fresh milk and UHT milk.

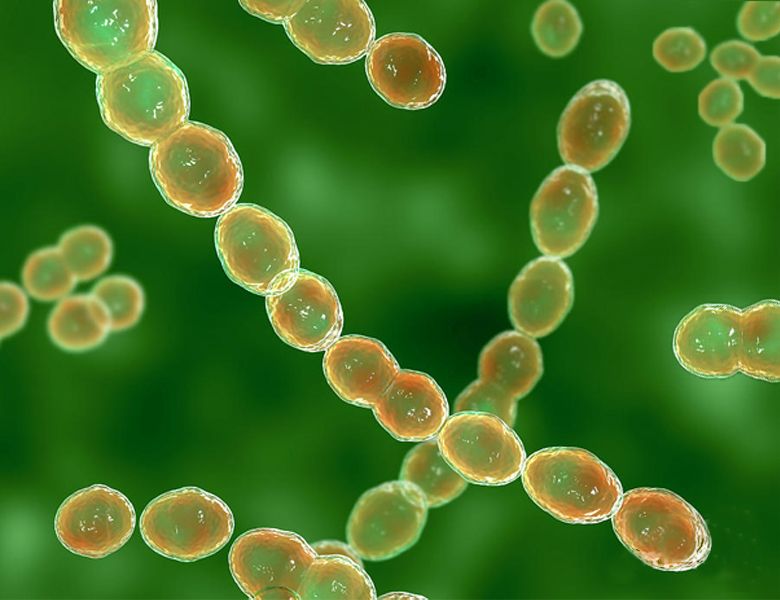

To produce ESL milk, a low original bacterial count in the raw milk is recommended. A microbial count of 100,000 cfu should not be exceeded.

ESL milk production

Indirect heating

The base product for ESL milk manufactured using indirect heating is heat-treated standardised milk. Indirect heating can be carried out using machines fitted with tubes or plates. In this method the milk flows through hot metal tubes or plates, whereby it is gradually heated and at the final stage the temperature is held at 127 °C for one to three seconds. In the final stage of processing the milk is cooled down gradually to its storage temperature of 5 °C.

Direct heating

The direct heating process also takes a standardised and heat-treated milk as its starting point. This is then normally heated in two stages to between 70 and 85 °C before being heated by direct contact with steam to a maximum of 127 °C. After around three seconds at this temperature, the milk is cooled down to between 70 and 85 °C under specific vacuum conditions inside what is known as a flash cooler, whereby the drop in temperature removes the steam that had been taken on. After a further cooling to 70 °C, the milk is then aseptically homogenised and is finally cooled down to 5 °C in stages.

Microfiltration

A combination method has been developed to further reduce the thermal stress placed on milk during the preservation process. This method firstly purifies the milk using a separator that splits it into skimmed milk and cream. The skimmed milk undergoes thorough sterilisation using microfiltration. This involves a technique called cross-flow filtration that uses ceramic membranes with a pore size of 0.8 to 1.4 μm. Most bacteria are between 0.6 and 1.0 μm in size and so can be held back by microfiltration. This method removes more than 99.5 per cent of the germs from the milk, which then collect in the microfiltration retentate. This retentate and the cream are then heated to an ultra-high temperature of between 90 and 110 °C for four to six seconds and are finally homogenised. Once the cream, skimmed milk and retentate have been combined to give milk of the desired fat content (skimmed, semi-skimmed, whole), the standardised milk is pasteurised and cooled down to its storage temperature.

Depth filtration

As with microfiltration, the depth filtration technique (carried over from the drinks industry) sees the milk firstly split into cream and skimmed milk by a separator. The cream that is needed to correct the fat content at a later stage is ultra heat treated and homogenised. The skimmed milk is passed through a pre-filter unit and a final filter unit, both of which consist of several polypropylene filter candles. The particles do not collect on the surface of these filter candles, but rather in the pores of the filter material itself. These pores measure 0.3 μm in the pre-filters and 0.2 μm in the final filters. The pre-filters capture around 80 per cent of the micro-organisms, as well as other solids found in milk. The two filters combined can capture over 99 per cent of the germs in the milk. After filtration, the milk is combined with the cream required to achieve the desired fat content and is then heated to 74 °C for 15 to 30 seconds. Lastly, the milk is cooled down to storage temperature.

Bacteria removal separation

The newest method for producing fresh milk with a longer shelf life is essentially an enhancement of the traditional process of pasteurising milk, with the integration of two bacteria removal separators connected in series before the skimming separator. This ensures that solids, bacteria and spores are removed from the entire raw milk flow mechanically and effectively. The spores that shorten milk’s shelf life have a higher specific density than skimmed milk and cream. Consequently, they can reliably be separated from the raw milk

using centrifugal force, i.e. with the two bacteria removal separators. The spores that are separated this way are then removed from the separator drums at regular intervals, and so do not remain in the milk. The fresh, pasteurised drinking milk produced using this method can have a shelf life of 20 days or more.

Given that the production of ESL milk involves the application of higher temperatures than those used to pasteurise milk, there are, as anticipated, minor changes to the molecular structure of the milk protein. However, this denaturation does not represent any loss in nutritional value – in fact, it makes the milk slightly more digestible.

By,

ATAMAD technical support sector

GET IN TOUCH

Copyright © 2023 Atamad.com All right reserved

Website design and SEO services by Seohama team – Web hosting by Sarverhama

Copyright © 2023 Atamad.com All right reserved

Website design and SEO services by Seohama team – Web hosting by Sarverhama