Exopolysaccharides (EPS)

- | آتاماد |

- Viewer: 164

Introduction:

The constituent units of polysaccharides are monosaccharides that are connected by glycosidic bonds, hence molecules with high molecular weight. Bacterial polysaccharides can also be produced by lactic acid bacteria and other bacteria. Since any microorganism can be in this type of production, each combination of chemical structure composition is different and gives different biological and functional characteristics.

Classification of polysaccharides

Polysaccharides can be classified into two general categories:

1- Capsular polysaccharides or oligosaccharides, which are attached to the outermost membrane of the bacteria like a sticky layer, are both a factor for bacteria to communicate with the outside environment and defend the cell against undesirable factors. Some of these compounds are able to be separated despite their strong binding to the membrane, but this probability is very low.

2- The second category is exopolysaccharides or EPS which, unlike capsular polysaccharides, do not have a strong connection with the bacterial membrane and are able to be released to the outside environment, and this brings benefits to various dairy and non-dairy products, such as: It has emulsifying, thickening and gel-forming properties for both bacterial cells, which can be mentioned to the formation of biofilm and the protection of bacterial cells against undesirable environmental conditions (such as phage attacks, toxic metals, pH and unfavorable temperature).

The production of these compounds depends on various factors such as the type of bacteria species, the type of strain, the composition of the culture medium (type of food and source of nitrogen and carbon), growth stage, pH and temperature conditions, and auxiliary bacteria. It can be said that the growth conditions of bacteria have the greatest effect on EPS production so that even in different environmental conditions, one strain of bacteria can produce different exopolysaccharides.

The production of exopolysaccharides, which are called natural thickeners, is possible in two ways:

1-Production inside the bacterial cell and then secreted to the outside environment.

2- Production by the enzymes secreted by the bacteria itself.

Classification of exopolysaccharides

As mentioned, exopolysaccharides are a class of polysaccharides that are composed of monosaccharide units, thus they can be divided into two groups based on the constituent units:

1- Homopolysaccharides or HoPS which consist of only one type of monosaccharide and fall into two categories:

The first category - glucans, which are produced by various species of lactic acid bacteria belonging to the genera Streptococcus, Lactobacillus, Leuconostoc, and Weissella, are created from D-glucose units and the location of their branching depends on the strain of the bacteria that produce it. For this reason, they are divided into two groups: α-glucans and β-glucans.

α-glucans include four categories of water-soluble dextran, water-soluble reuteran, alternan with high solubility in water but low viscosity, and water-insoluble mutants, and β-glucans produced by Streptococcus and Pediococcus and from D-glucose units are formed.

The second category - fructans or galactans, consists of D-fructose or D-galactose units. Fructans are classified into two groups: levan and inulin, which are soluble in water and are produced by different species, the most well-known of which are Streptococcus salivarius, Leuconostoc mesenteriodes, and Lactobacillus johnsonii did water-soluble galactans, which are less abundant than fructans, are produced by Lactococcus lactis subsp. lactis, Lactobacillus delbrueckii subsp. Bulgaricus and Weissella confusa are produced.

2- Heteropolysaccharides or HePS are produced from two or more different types of branched or unbranched monosaccharides, such as hexose, N-acetylated monosaccharides, pentose and uronic acids and are produced by Streptococcus, Lactobacillus and Lactococcus. These bacteria create a small amount of heteropolysaccharides, but in this small amount, they bring a lot of consistency and cohesion, such as kefir, which is produced by several species of lactobacillus in kefir grains. Other hetero bacteria that are soluble in water are xanthan and gellan, which are produced by non-lactic acid bacteria.

In general, exopolysaccharides are mainly in the hetero form and are produced inside the lactic acid cells of bacteria.

In the following, we discuss the use of exopolysaccharides in various industries:

Yogurt

Yogurt is one of the most common fermented products around the world, which is produced by starter cultures that contain two bacteria, Streptococcus thermophilus and Lactobacillus bugaricus, in equal amounts. In the production of yogurt, bulgaricus first comes into action and provides the necessary materials for the growth of thermophilus, which are mainly amino acids, and then by producing metabolites such as formic acid and carbon dioxide, the growth of bulgaricus is stimulated.

One of the most important subjects in yogurt production is product quality stability, both in terms of texture and flavor. Thermophilus and bulgaricus each produce a normal taste and a sour taste in yogurt, respectively. In order to create a suitable tissue, it is very important to choose starter cultures that contain strains with the desired amount of EPS. In general, thermophilus 0.89-0.030 and bulgaricus 0.057-0.424 grams per liter of exopolysaccharides produce and create different rheological properties such as firmness, consistency, smoothness and viscosity in different yogurts (set and mixed).

In non-industrial yogurts, syneresis is common in the product and natural yogurt bacteria are responsible for creating the texture. One of the disadvantages of texture in yogurt is the problem of syneresis in them. In industrial production, to overcome this defect, by adding dry ingredients that create the texture of the product, such as calcium and sodium caseinate, whey protein, skim milk powder, and stabilizers such as gums, modified starch and gelatin, the dry matter is increased by 14% and syneresis is corrected. But this method causes producers to incur additional costs and can change the quality of the product. That is why in some countries, rules have been specified for the use of these materials. By using EPS producing strains, we can hope to reduce or even eliminate them and and produce products with higher viscosity and water holding capacity, smooth, uniform and creamy texture.

Yogurt texture consists of casein network and fat globules, whose spaces are occupied by lactic acid cells of bacteria and serum.

LAB bacteria are classified into three categories in terms of texture and consistency:

Bacteria that produce both capsular EPS and slime EPS, the second category of bacteria that produce only capsular EPS, and the third category of bacteria that do not produce any EPS. do

Bacteria capable of producing both capsular and slime EPS are used in the production of yogurt starters. Even though slimy EPS leads to an increase in the viscosity of the product, its excessive production in the mouth is quite clear and seems undesirable. Meanwhile, the amount of EPS in capsules is The reason is that it is directly related to the size of the bacterial cell, it is not produced in a large amount.

In a study, it was shown that starters containing capsular EPS-producing strains (without slime) produced a more stable product with less syneresis and a smoother texture than starters containing bacteria that are unable to synthesize capsular EPS. Among other advantages, it can be mentioned that the capsules limit the production of lactic acid and finally, by stopping the production of acid by the bacterial cells, they prevent sour taste in yogurt.

In an experiment, the texture of yogurts produced with negative EPS strain was investigated. Since exopolysaccharides never change the flavor and taste of the product and are only effective on the textural characteristics of the product, by using strains that produce EPS instead of negative EPS strains, the viscosity of the product 16-21% increase and water holding capacity improved.

The effect of EPS on cheese quality

Today, the use of low-fat dairy products is of particular importance among consumers, but as we know, the challenges of these products are dry, grainy and rubbery texture, as well as poor flavor. It is in them that these items must be corrected by the manufacturer.

Currently, the use of lactic acid bacteria in cheese production as a fermentation starter or as an adjunct to fix these defects is very common. It should be noted that because high-fat cheeses do not have the disadvantages of low-fat cheeses in terms of texture and taste, they have been less investigated and the main focus is on low-fat cheeses.

During the research, it was found that exopolysaccharides lead to the improvement of the quality of low-fat cheeses and finally provide a similar high-fat product.

The problem of syneresis in fresh cheeses is more severe than cheeses that require a special ripening period, which is due to the high water content in these cheeses. By using EPS producing strains in the production of fresh low-fat cheeses, the dry and brittle texture that occurs after syneresis turns into a soft and creamy texture, while it is possible to use a smaller amount of hydrocolloids or eliminate them altogether.

In the production of mozzarella cheese, which is one of the most common cheeses used on pizza, different thermophilic starter cultures are used. Among the performance characteristics of this product, elasticity and melting are sufficient, but low-fat mozzarella is devoid of these characteristics. To overcome this problem, by using exopolysaccharide producing strains, the moisture content of cheese can be increased by 2-7% and the desired properties can be improved.

The same results as the mentioned cheeses were also observed in other low-fat cheeses. For example, in the production of semi-fat cheddar cheese, a special strain of Lactococcus lactis that produced EPS was used. The produced exopolysaccharides had no interference with the fermentation starter strains or even the strains that are active during cheese ripening, and in terms of rheological characteristics such as taste and mouthfeel and texture, it was similar to full-fat cheddar cheese. Also, by adding Lactobacillus plantarum, which produces exopolysaccharide, a cheese with high moisture, high proteolysis and less hardness was obtained.

The effect of EPS on other fermented milk drinks

One of the drinks obtained from milk fermentation is kefir, which contains a little gas and also ethanol (about 0.1-1%). In traditional kefir production, kefir grains contain lactic acid bacteria (hetero and homo), acetic acid bacteria and yeasts, but in the industrial method, kefir starter is used instead of kefir grains. During the fermentation process, kefir, which is a water-soluble exopolysaccharide with an equal amount of glucose and galactose, is produced mainly by Lactobacillus Kefiranofaciens and also by other LAB such as Lactobacillus planetarum, Leuconostoc mesenteroides, Lactobacillus paracasei, etc.

The noteworthy point is that kefir grains are not only used for kefir drinks, but these grains are also used for a series of non-dairy products that have a more complex community of sugars, and this variety Bacterial and yeasty kefir grains are non-dairy which causes the instability of production in such products.

Dahi is also a traditional milk-based yogurt in South Asia, that its fat is usually 3.5-8%, but to produce low-fat Dahi, they use lactic acid bacteria, which creates EPS, to improve the taste and texture.

Other drinks include Viili, Langfil and Tette in the Scandinavian region, which use thermophilic and mesophilic lactic acid (optionally) and mold and yeasts in their production.

Application of EPS in non-dairy products

Apart from dairy products, the lactic acid of can be used in Plant-Based Beverages (to have a good taste and texture and to create a mouthfeel), in the bakery industry (to have a positive effect on dough stability and finally to improve the texture and volume of bread in products with Low sugar content and also used as a fat substitute, maintaining the quality of frozen dough products and gluten-free products) and in low-fat meat products (for texture modification and other technological features, for example, in fermented sausages).

Providing health benefits

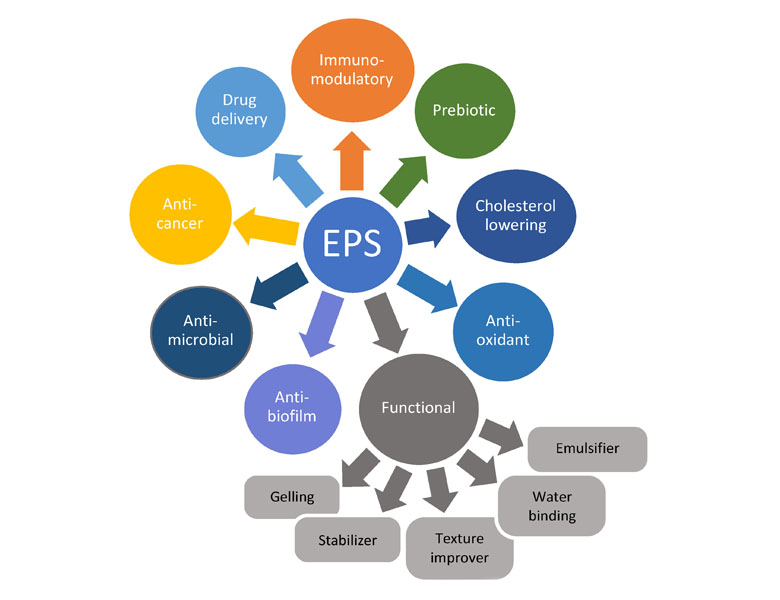

Researchers have recently investigated the lactic acid activity of bacteria and their potential in EPS production in different parts of food and medicine production. Research in this field is still continuing. Considering that the activity and function of EPS depends on various factors such as its type (hetero or homo), molecular weight, and monosaccharide composition, by conducting more detailed research on their structure, it is possible to produce EPS with desirable characteristics. and it was achieved according to the desired industry and apart from the technological advantages that these compounds contain, it took advantage of their positive characteristics in the health subdivision. For example, the lactic acid of bacteria that create exopolysaccharides causes more fermentation products to stop in the digestive system and more colonies are produced by probiotic bacteria in the intestine (in fact, these compounds are prebiotics). Anti-cancer activity, anti-wound, antioxidant activity, regulation of the body's immune system, reduction of blood cholesterol, etc. are other examples that will be discussed more in future articles.

Reference:

Jurášková D, Ribeiro SC, Silva CCG. Exopolysaccharides Produced by Lactic Acid Bacteria: From Biosynthesis to Health-Promoting Properties. Foods. 2022 Jan. DOI: 10.3390/foods11020156.

Berthold-Pluta, Anna & St, Antoni & Pluta, et al. Exopolysaccharide-producing lactic acid bacteria -health-promoting properties and application in the dairy industry. Advancements of Microbiology .2019 Mar. DOI: https://doi.org/10.21307/PM-2019.58.2.191

GET IN TOUCH

Copyright © 2023 Atamad.com All right reserved

Website design and SEO services by Seohama team – Web hosting by Sarverhama

Copyright © 2023 Atamad.com All right reserved

Website design and SEO services by Seohama team – Web hosting by Sarverhama