- آتاماد

- Practical applications of gums and stabilisers in dairy Foods (Second Part)

Practical applications of gums and stabilisers in dairy Foods (Second Part)

- | user2 |

- Viewer: 1258

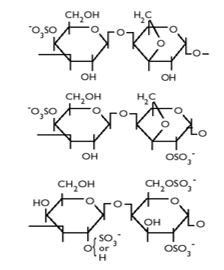

Practical applications of gums and stabilisers in dairy Foods (Second Part), Carrageenan: Carrageenan is a natural carbohydrate (polysaccharide)

obtained from edible red seaweeds.

Interactions with proteins:

• k-Carrageenan stabilizes milk k-casein products due to its charge interaction with the casein micelles (~200 nm diameter); their incorporation into the network preventing whey separation.

• k-Carrageenan’s ability to complex with milk proteins leads to the formation of a weak thixotropic gel structure which will suspend cocoain chocolate milk at 0.02% and form milk gels, such as flans, at 0.20%.

• k-Carrageenan is also used as a binder in cooked meats, to firm sausages and as a thickener in toothpaste and puddings.

Xanthan Gum:

Xanthan gum is an extracellular polysaccharide secreted by the micro-organism Xanthomonas campestris. Xanthan gum is soluble in cold water and solutions exhibit highly pseudoplastic flow. Its viscosity has excellent stability over a wide pH and temperature range and the polysaccharide is resistant to enzymatic degradation. Xanthan gum exhibits a synergistic interaction with galacto-mannans such as guar gum and locust bean gum (LBG) and the glucomannan konjac mannan. This results in enhanced viscosity with guar gum and soft, elastic thermally reversible gels with LBG and konjac mannan. Blends of xanthan gum, carrageenan and galactomannans are excellent stabilisers for a range of frozen and chilled dairy products such as ice cream, sherbet, sour cream, sterile whipping cream and recombined milk. These economical blends are available pre-prepared to provide optimal viscosity, long- term stability, improved heat transfer during processing, heat shock protection.

Microcrystallinecellulose (MCC):

Microcrystalline cellulose (MCC) has been used for over 40 years to provide physical stability and texture modification in a wide variety of food applications.

MCC crystals do not dissolve in water, but the colloidal form hydrates to form thixotropic gels that can stabilize foams, replace fat, and control ice-crystal growth.

Heat Stability–MCC is stable during heat processing, including baking, retorting, UHT processing and microwave heating with minimal loss in viscosity.

Shorten Textures–shorten textures or add body without creating a gummy or pasty texture →cleaner mouthfeel and excellent flavor release.

Replace Fats and Oils –mimics the flow behaviour of oil emulsions.

Control Ice Crystal Growth –the 3-dimensional matrix of colloidal MCC and the surface area of the microcrystals retards ice crystals growth during freeze/thaw cycles. Generally effective in maintaining the three phase system of water/fat/air.

Opacity –insoluble cellulose crystallites act as opacifiers and can add whiteness to products.

Starch:

No other single food ingredient compares with starch in terms of sheer versatility of application in the food industry. Second only to cellulose in natural abundance, this polymeric carbohydrate was designed by nature as a plant energy reserve. Man, however, has extended the use of starch far beyond this original design. Modifications - physical, chemical or biochemical -mean that numerous highly functional derivatives have enabled the evolution of new processing technologies and market trends.

Starch selection will be influenced not only by the process requirements but also by the product characteristics. Typically, 1±3% starch is used for pouring consistencies, 3±4% for medium viscosity and 4±6% for thick, spoonable textures. Gelled textures, as in cheese analogues, are achievable with some converted starches or high amylose starches. Gelled dairy desserts will also use other hydrocolloids, notably carrageenans, in combination with starch to create the desired textures.

Pectin:

Pectins belong to the group of hetero-polysaccharides and are present in all plant primary cell walls. Depending on the molecular composition there are different types of pectin characterising themselves particularly by different gelling mechanisms.

Pectin can have two distinct functions in dairy products and dairy analogues such as those prepared from soya. High ester pectins can act as protein dispersion stabilisers at reduced pH. Typical examples include yoghurt drinks, milk/fruit juice drinks, acidified whey drinks and acidified soy drinks. Low ester pectins behave quite differently, and can be used to gel neutral milk desserts or as texturiser in more acid products (e.g., stirred yoghurt) by interaction with calcium and milk proteins.

Reference:

Phillips, Glyn O., and Peter A. Williams, eds. Handbook of hydrocolloids. Boca Raton, FL: CRC press, 2000.

Practical applications of gums and stabilisers in dairy Foods. Matt Golding & Lara Matia-Merino IFNHH

GET IN TOUCH

Copyright © 2023 Atamad.com All right reserved

Website design and SEO services by Seohama team – Web hosting by Sarverhama

Copyright © 2023 Atamad.com All right reserved

Website design and SEO services by Seohama team – Web hosting by Sarverhama