Factors affecting EPS production by LAB strains

- | آتاماد |

- Viewer: 108

In the previous article, EPS classification, application in the food industry, and health issues were discussed. In this topic, the factors affecting the synthesis of exopolysaccharides by lactic acid bacteria will be reviewed.

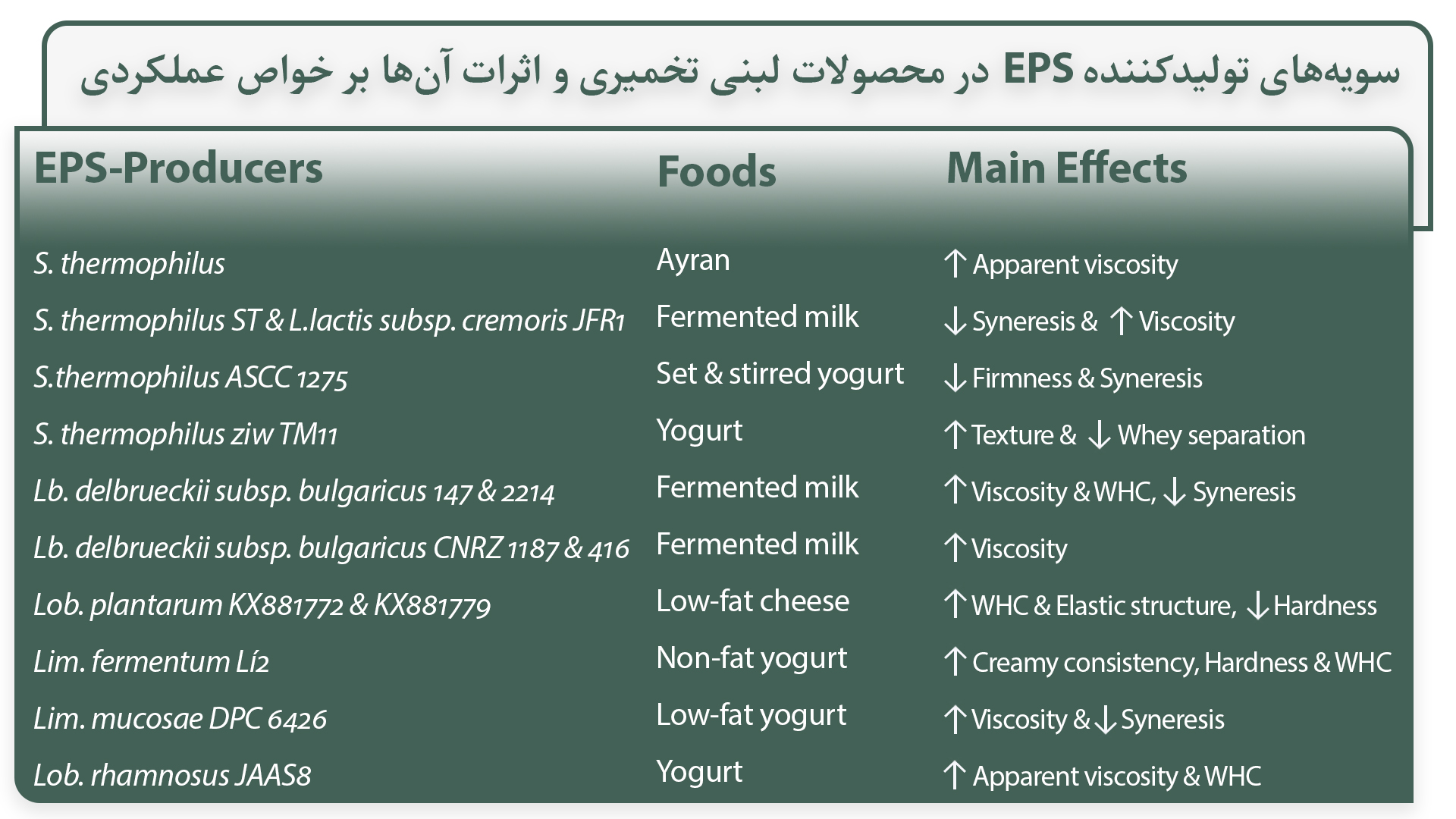

Different types of lactic acid bacteria can produce exopolysaccharides under different factors. For example, S. thermophilus produces 0.1 g/liter of EPS. While lactobacilli such as L. fermentum, Lb. plantarum, and Lb. bulgaricus produce 0.75, 0.75, and 0.06-0.15 g/L EPS, respectively.

Currently, the highest amount of exopolysaccharide production belongs to certain subspecies of Lb. kefiranofaciens (2.5 g/L), Lb. plantarum (2.8 g/L), and Lb. rhamnosus (2.8 /L).

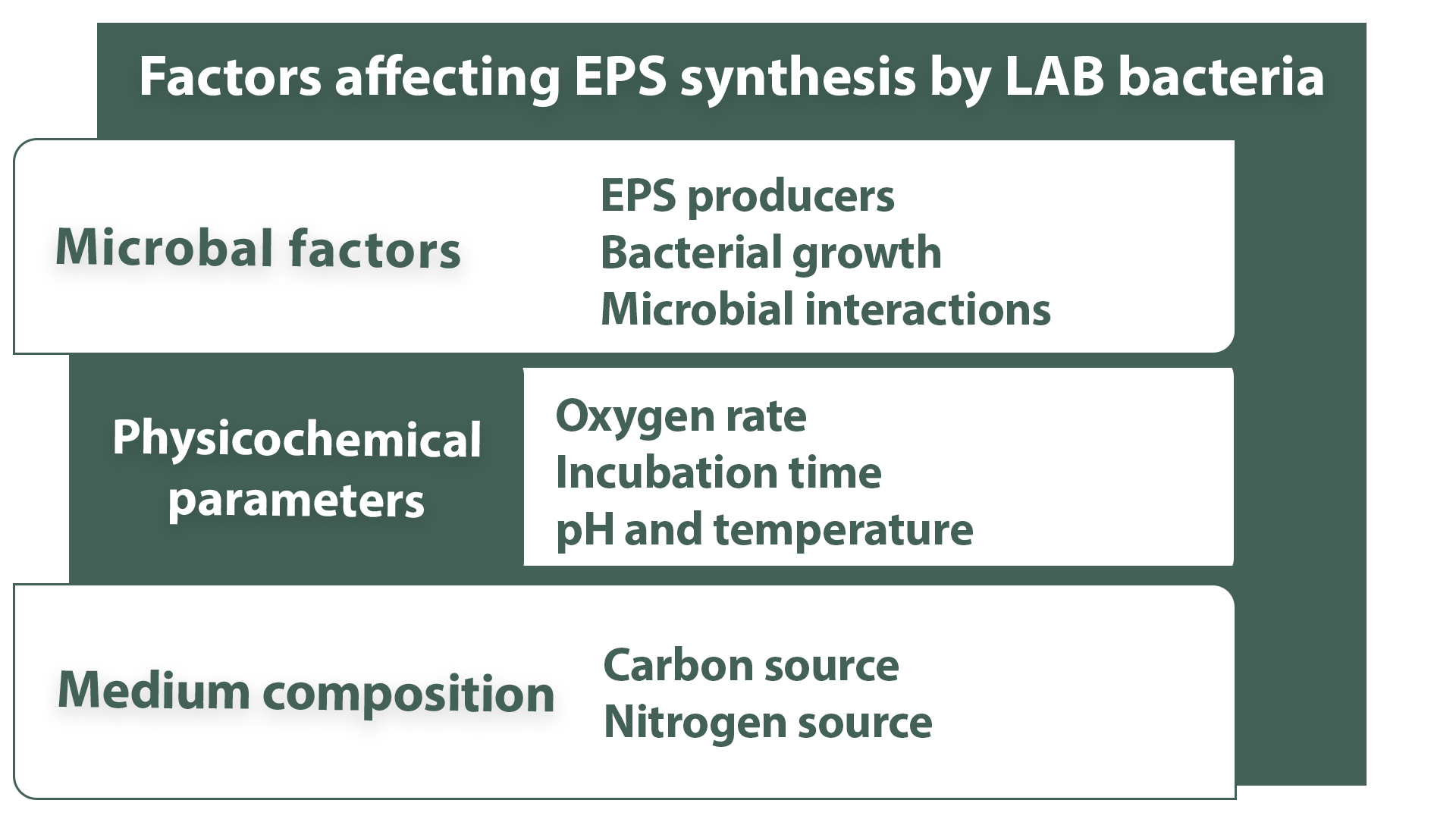

Among the various factors that play important roles in the synthesis of exopolysaccharide, we can mention the composition of the culture medium, such as nitrogen and carbon sources, temperature, acidity, the growth stage of bacteria, and also adjuvant microflora.

1. The composition of the culture medium

The effect of culture medium on LAB to synthesis EPS synthesis has been reported. The growth conditions of bacteria, or in other words, the composition of the culture medium, which includes the type of carbon and nitrogen, has a great impact on the production of exopolysaccharides, but the composition of monosaccharides, which are the building blocks of EPS, is not necessarily dependent on the carbon source available to bacteria. The important issue is that from a practical point of view, in different growth conditions, one strain may produce different EPSs.

Carbon sources:

By examining the results obtained from different bacteria in different culture environments, you can get a better understanding of this issue:

- Lb. bulgaricus and Lb. casei in two culture mediums, M17 Broth (rich in nitrogen and carbon) and plain milk, produces different amounts of exopolysaccharide. In this example, the EPS production in M17 Broth medium is more than twice that in the milk medium. Interestingly, since the ratio of exopolysaccharide produced by S. thermophilus is vice versa, milk is described as a more suitable medium for S. thermophilus.

- The amount of kefiran, which is produced by a group of related bacteria, is also different under the influence of disaccharides, which are carbon sources, such that in the environment rich in lactose, that is 4.3%, and in the environment containing sucrose, this amount reached 3.8%, but kefiran amount was lower in environments containing fructose and glucose.

- The amount of exopolysaccharide produced by L. fermentum was in its highest state in the environment containing glucose compared to fructose, lactose, and galactose.

- A special strain of S. thermophilus, which was isolated from Bulgarian homemade yogurt, produced more exopolysaccharides in the medium containing sucrose than in the medium containing lactose.

According to these examples, it can be understood that by modifying the carbon sources in milk, it can be turned into a suitable environment for the production of exopolysaccharide compounds.

Nitrogen source:

Another effective compound for the production of exopolysaccharides in the culture medium is the nitrogen source. For example, kefiran production largely depends on the nitrogen source. Research has shown that in the presence of organic nitrogen, this amount is higher than when the culture medium contains inorganic nitrogen. In addition, with the variety of nitrogen (both organic and inorganic), different amounts of kefiran are produced. For example, the culture medium containing casein, which is a type of organic nitrogen, leads to the production of the most kefiran, and in the presence of peptone, tryptophan, and yeast extract, this amount is less. On the other hand, it is less in environments containing ammonium chloride and ammonium sulfate, which are inorganic nitrogen.

2. Physicochemical parameters

In addition to bacterial growth, physicochemical parameters also affect EPS production by LAB.

Temperature

Temperature has a great effect on the production of exopolysaccharides by LAB. According to the research, the maximum production of these compounds occurs at a temperature lower than the optimal temperature for each strain (18–25°C for mesophilic and 35–37°C for thermophilic species), due to physiological stress induced by the reduced temperature on bacterial cells, particularly in strains lacking proteolytic activity like S. thermophilus.

In an experiment, the effect of temperature on S. thermophilus was investigated. Considering that the optimum growth temperature for this bacteria is 42°C, to prove this, a temperature of 37°C was chosen. Regardless of the composition of the culture medium, at less than the optimal growth temperature, the production of exopolysaccharide increased significantly. This means that even in skim milk, at 37°C, EPS production was five times higher than at 42°C. Other examples:

- Lb. delbrüeckii subsp. Bulgaricus, with its optimal growth temperature of 40°C, produces more exopolysaccharides at 30-40°C. Also, EPS synthesis decreased by half at 45°C.

- As for the synthesis of kefiran, although the optimum growth temperature for kefir grains is 37°C, the lowest and highest amount of EPS is synthesized at 37°C and 25°C respectively.

- On the other hand, there have been reports that L. fermentum and Lb. casei at 37°C, which is the optimal growth temperature, synthesize the highest amount of exopolysaccharide.

- By experimenting on Lc. Lactis subsp. Cremoris, temperature did not show an effect on the production of exopolysaccharide.

Fermentation time

The duration of incubation plays an important role in the synthesis of exopolysaccharides by lactic acid bacteria. By examining the growth chart of L. fermentum, it was found that in the stationary growth phase, after 32 hours, with the production of glycohydrolase, which is a catalyst for the destruction of polysaccharides, the number of exopolysaccharides decreases, and of course, the reduction of these compounds after long-term incubation is similar in other strains. The noteworthy point Is that at a temperature and pH lower than the optimal growth of any bacteria, the destruction and ultimately the reduction of exopolysaccharide is less.

pH

In the case of some bacteria such as S. thermophilus, because the highest amount of EPS is made at the end of fermentation, the content of EPS does not change during fermentation. In general, as we know, different species and strains of bacteria differ in their pH requirements for growth, but on average it is around 6. For example, the highest bacterial growth and EPS production by S. thermophilus and Lb. delbrüeckii subsp. Bulgaricus is at pH 6.2 and 6.5 respectively. But in the case of bacteria L. fermentum, although the optimal growth pH is around 7, at a slightly lower pH of 6.5, there are the highest EPS production rates. It was also suggested that low pH (4.9) significantly affects the degradation of EPS and leads to a decrease in its production efficiency.

3. Bacterial factors

EPS-producing bacteria strain and species

As stated above, different bacterial species/ strains influence EPS production. The different behavior of strains in terms of EPS production has been corroborated by different studies. It has been revealed that different strains of Weissella cibaria showed about 2.8-fold variance in EPS production in sucrose-MRS broth. Similarly, it has been demonstrated that different strains of Lpb. plantarum isolated from different sources, Turkish sourdough and cow milk, have different EPS production. In another study, it was demonstrated that different strains of Leuconostoc mesenteroides produce exopolysaccharides with different concentrations.

This different behavior of LAB in terms of EPS production could be explained through changes in gene expression in response to stress conditions. For instance, a glycosyltransferase related to EPS synthesis was upregulated after exposure to acidic stress, bile salts, and osmotic stress in B. animalis subsp. lactis. Other studies demonstrated this overexpression of genes related to EPS production in other species such as S. thermophilus and Lcb. paracasei when stressing conditions are encountered.

The presence of other bacteria in the starter culture mixture

As we know, in the production of industrial starters, a different bacterial composition is used. Different species can be effective in the production of EPS. In such a way that by producing metabolites such as bacteriocins, they have an inhibitory effect on each other and disrupt the production of EPS, or like yogurt bacteria (Lb. bulgaricus and S. thermophilus) to intensify the production of these compounds with the cooperation of both species.

In the products that consist of a mixture of EPS-producing strains and other strains that do not synthesize EPS, the type of EPS is indirectly formed in a way that can lead to favorable changes in the final product.

Bottom line

The ability to produce EPS by LAB depends on several factors, and the amount of production is largely species- and strain-specific. Physicochemical parameters influencing bacterial growth (i.e., temperature, incubation time, pH, oxygen rate, etc.) as well as different carbon and nitrogen sources are the main factors affecting EPS production. Moreover, the same LAB strain can synthesize various EPS under different growth conditions. The composition of the culture medium, including added nutrients as growth enhancers, is one of the most important factors affecting EPS production.

References:

Prete, Roberta, Mohammad Khairul Alam, Giorgia Perpetuini, Carlo Perla, Paola Pittia, and Aldo Corsett. "Lactic Acid Bacteria Exopolysaccharides Producers: A Sustainable Tool for Functional Foods". Foods. 2021. DOI: 10.3390/foods10071653.

Berthold-Pluta A., Pluta A., Garbowska M., and Stasiak-Różańska L. Exopolysaccharide-Producing Lactic Acid Bacteria – Health-Promoting Properties And Application In The Dairy Industry. Advancements of Microbiology. 2019. DOI: https://doi.org/10.21307/PM-2019.58.2.191

GET IN TOUCH

Copyright © 2023 Atamad.com All right reserved

Website design and SEO services by Seohama team – Web hosting by Sarverhama

Copyright © 2023 Atamad.com All right reserved

Website design and SEO services by Seohama team – Web hosting by Sarverhama