Using dairy waste to produce biodegradable packaging

- | آتاماد | News |

- 316

Packaging is essential to maintaining and protecting the quality of the cheese product and also to attract the attention of consumers.

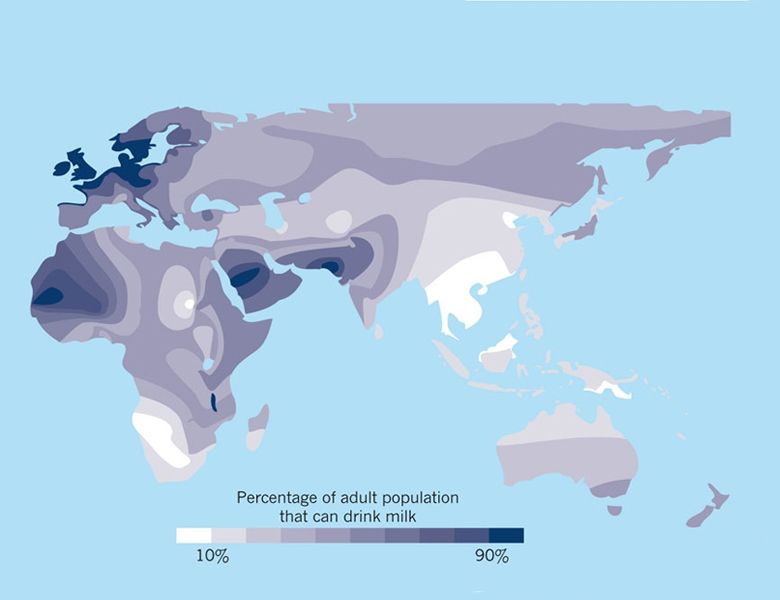

Currently, most plastics and packaging are made from fossil fuels, which are not renewable. In addition, many traditional fossil fuel-based plastics do not degrade easily. It is possible to make biodegradable plastics using chemicals derived from fossil fuels, but a much better option is to make bioplastics using materials such as corn starch, vegetable fats, oils, etc. At this time, only about 1% of plastics are bio-based, which, in addition to being produced with sustainable resources, can be biodegradable and/or compostable.

The dairy industry can help innovation in the production of bioplastics. At the Center for Dairy Research (CDR), research on methods of producing bioplastics from dairy waste is supported. Dr. Erica Majumder, a professor of bacteriology at the University of Wisconsin-Madison, is engineering microorganisms to ferment low-value acid whey into PHB (polyhydroxbutrate), a polymer that can be used to make a wide range of biodegradable plastics.

Another exciting project is underway by Dr. Tim Donohue, professor of bacteriology at the University of Wisconsin-Madison. He is investigating the production of pure lactic acid from biofermentation of cheese whey. Pure lactic acid can be used to make polylactic acid, which is a renewable and biodegradable bioplastic.

One of the challenges of these innovations is measuring these technologies from the stage of basic research to industrial production. This is something that CDR wants to help with. The Dairy Business Innovation Alliance (managed by CDR and the Wisconsin Cheesemakers Association) received supplemental funding from the USDA that will be used to purchase larger bioreactors to evaluate the commercial viability of these new biofermentation processes. The CDR also receives specialized pilot-scale equipment that can purify new green chemicals produced from these biofermentations.

While carbon footprint reduction and sustainability have been the main focus, there are other innovations in packaging that are interesting. For example, some packages may use QR codes to provide more information to consumers. People can scan the QR code and learn more about the story of the manufacturer who made the product or the farm where the milk came from. This can be especially effective for smaller producers who want to tell the story behind their products.

Another issue that can be briefly mentioned is food waste, which is an important global problem, because a huge amount of it ends up in landfills. In general, better packaging materials and shelf-life processes can help reduce food waste by maintaining product quality (less spoilage).

All in all, moving from traditional fossil-based plastics to biodegradable plastics is possible, some of which can be made with renewable dairy whey. This requires a lot of effort and innovation, including the need to engineer microorganisms to produce green chemicals, as well as developing cost-effective methods to isolate the target chemicals produced in the bioreactor. The investment in this process is worth it, and it is a big step forward in packaging.

Reference:

https://www.dairyfoods.com/articles/96323-sustainable-innovations-in-cheese-packaging

GET IN TOUCH

Copyright © 2023 Atamad.com All right reserved

Website design and SEO services by Seohama team – Web hosting by Sarverhama

Copyright © 2023 Atamad.com All right reserved

Website design and SEO services by Seohama team – Web hosting by Sarverhama